Wrinkle Removing Roll

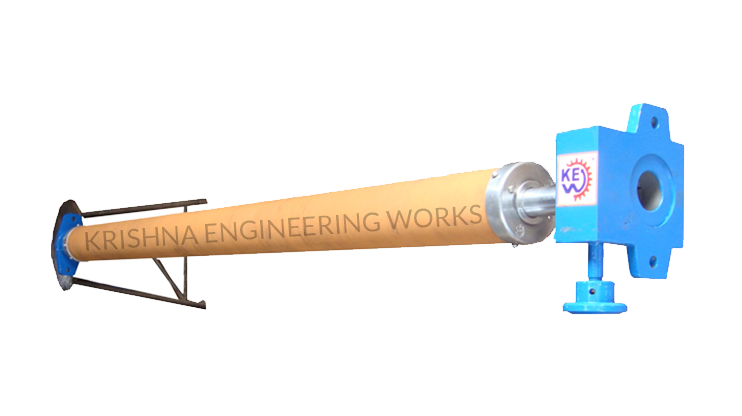

Manufacturer, Exporter and Supplier all types of Wrinkle Removing Roll from India like, Bow Roll, Banana Roll, Expander Roll, Metal Expander Roll, Slat Expander Roll and more. This is the most commonly used wrinkle remover device. It mainly consists of bowed shaft, metal segments, sealed ball bearings, abrasion resistant, rubber sleeve etc. Krishna Engineering Works incorporated into manufacturing and exporting business of Wrinkle Removing Roll, and Bow Roll from India. Our skilled engineers have designed bow roll for the application to get maximum result from wrinkles. We ensure to get premium quality of wrinkle removing roll, Bow Roll with meeting international industrial standards. We make Expander Rollers having very wide range of dimensions and suitable for equally wide range of applications and web materials. They are supplied with mounting brackets, which could be either wall mounting or foot mounting.

The Expander Rollers we offer consist of bowed shafts, sealed ball bearings, abrasion resistant sleeve and metal segments. These are widely used as wrinkle remover devices in various industries and are available with us in various dimensions. Further, these are also supplied with gear set and mounting brackets which can either be Foot Mounted or Wall Mounted.

Application

Wrinkle Removing Roll

Used in Different Industries : Industries Like Paper, Tyrecord, Plastic Packaging, Woven Sacks, Pharmaceuticals, Leather, Textile, Plywood, Sheet Line Material Handeling and many more.

Our equipments are used for following Applications:

- Rewinding – Converting, Textile, Paper, Tire

- Unwinding – Converting, Textile, Paper, Tire

- Marking, Coding and Printing Applications

- Slitting – Any type of Laminate

- Packaging

- Wrapping

- Printing – Converting and Textile

- Tracking

- Controlling Tension & Edge of Laminate / Fabric.

Roller used in Different Machines for Plastic Industry

|

Roller used in Different Machines for Textile Industry

- Stentor Machine

- Jigger Machine

- Rotary Machine

- Dyeing Machine

- Calender Machine

- Mangle Machine

- Loop Steamer

Technical Specification

- Rubber Sleeve Covered. (High Quality Synthetic Nitride Sleeve).

- Metal Expander with hard chrome plated surface for high speed application.

- Vary Bow Expander Roller.

Standard Features

- Single Acting Bow Roll

- Double Acting Bow Roll

The Performance of our Bow Roller depends upon the following points:

- Wrap angle

- Lead-in & Lead-out distance

- Position of bow (Adjustable)

In this, 3:1 (lead-in: lead-out) ratio is considered to be the perfect. The best results are attained when Bow Roller is perpendicular to the web direction.

Advantages of our Bow Roll are:

- Control Slack Edges

- Remove wrinkles

- Separate slit webs on winder

- Eliminate baggy center

- Try to even out lateral tension across the web width